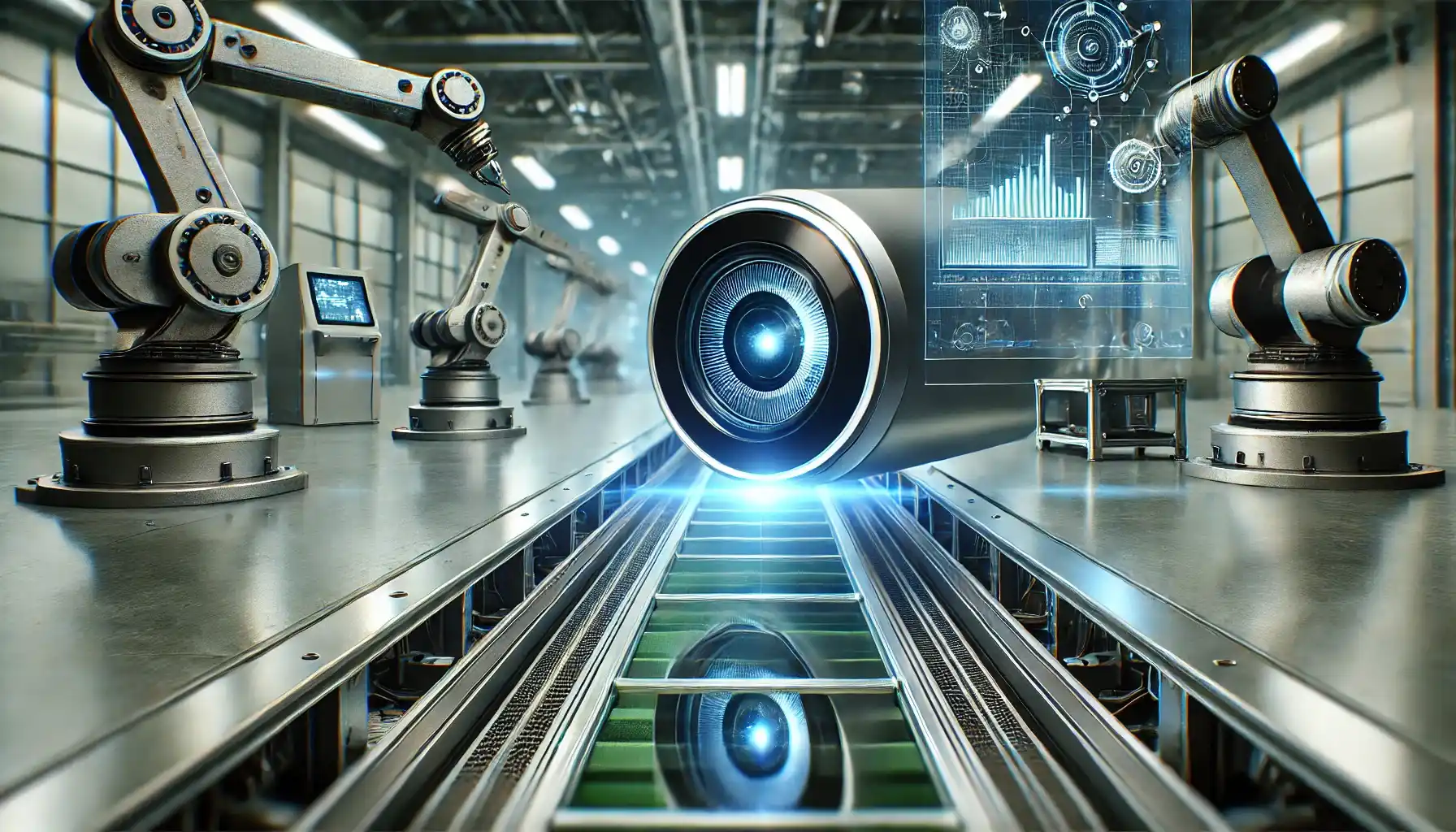

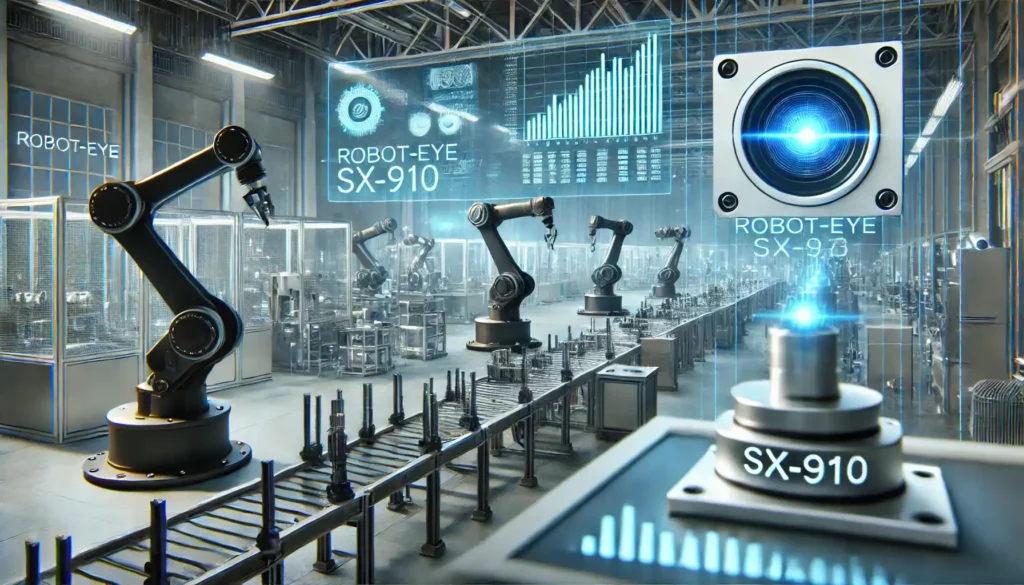

In an era where speed and accuracy are paramount, precision sensors and cutting-edge vision systems have become the cornerstone of modern robotics. One name stands out among these innovative solutions: the Robot-Eye SX-910. Designed to bring unparalleled clarity and responsiveness to robots in various industries, this state-of-the-art vision sensor is fueling a new wave of automation capabilities. From efficient assembly lines to advanced quality control, the Robot-Eye SX-910 is not just an add-on—it’s quickly becoming a vital component in the robotics landscape.

Table of Contents

Unveiling the Potential of Robot-Eye SX-910

As manufacturing and automation continue to advance at breakneck speed, the necessity for reliable and precise sensor technology cannot be overstated. The Robot-Eye SX-910 meets these needs by providing high-resolution vision and robust real-time data processing. Its unique architecture combines intelligent algorithms with sophisticated optics, facilitating rapid decision-making on the production floor.

Key Features and Technical Specifications

- High-Resolution Imaging:

The Robot-Eye SX-910 boasts a superior high-resolution camera capable of capturing minute details in a fraction of a second. Whether it’s used for microscopic inspections or scanning large, fast-moving conveyor belts, this sensor reliably delivers sharp images. - Advanced Data Processing:

Equipped with a powerful onboard processor, the Robot-Eye SX-910 can analyze images and detect anomalies almost instantly. Its machine learning algorithms can identify objects, measure dimensions, and even adapt to changing lighting conditions. - Rugged Durability:

Industrial environments can be harsh, with temperature fluctuations, dust, and vibrations. The SX-910 is designed to withstand these conditions. With its reinforced casing and built-in shock absorbers, it consistently delivers peak performance in challenging settings. - Easy Integration:

Seamless compatibility with existing robotic platforms sets the Robot-Eye SX-910 apart. Its plug-and-play design means minimal downtime for installation, enabling businesses to quickly incorporate it into their workflows.

By streamlining the process of data collection and interpretation, the Robot-Eye SX-910 helps robots execute tasks more effectively. The result is heightened productivity, improved safety, and more reliable outcomes across a broad range of applications.

How Robot-Eye SX-910 Elevates Automation

Revolutionizing Quality Control

One of the biggest challenges in quality control is consistency. Human inspectors can fatigue over long shifts, and even slight lapses in attention can compromise quality. With the Robot-Eye SX-910, automated vision inspections remain sharp 24/7. The sensor’s machine learning algorithms can detect and categorize defects faster than the human eye, reducing waste and ensuring only top-quality products reach the end customer.

Enhancing Pick-and-Place Operations

Pick-and-place robots rely heavily on accurate object detection. Even slight misjudgments in position can cause disruption along the assembly line, leading to delayed production. By leveraging the SX-910’s pinpoint accuracy, robots can grasp items with exceptional precision, optimizing cycle times and minimizing errors. This high level of accuracy is invaluable in electronics manufacturing, pharmaceuticals, and other precision-driven industries.

Automated Assembly and Welding

The Robot-Eye SX-910’s real-time data processing capability makes it an excellent choice for tasks requiring tight tolerances, such as automated assembly or welding. Its sophisticated image recognition software detects even microscopic misalignments, allowing industrial arms to correct their positions on the fly. This precision results in durable, high-quality welds and assemblies—an outcome that directly boosts product reliability and safety.

The Benefits of Integrating Robot-Eye SX-910

Integrating a vision solution like the Robot-Eye SX-910 has significant advantages. From improving overall equipment effectiveness (OEE) to driving better decision-making through data analytics, the sensor’s impact on an automated system can be transformative.

Enhanced Efficiency and Throughput

Efficient production hinges on speedy, accurate processes. When paired with industrial robots, the SX-910 ensures minimal downtime. Malfunctions or anomalies are identified in real-time, so corrective actions can be taken swiftly. With faster inspections and coordinated operations, the entire manufacturing process benefits from a higher throughput without compromising quality.

Improved Worker Safety

While robots excel at repetitive and hazardous tasks, their effectiveness depends on reliable vision systems. A sensor that misjudges distances or positions can cause accidents in the workspace. Thanks to the Robot-Eye SX-910’s robust design and continuous calibration features, the likelihood of accidents diminishes significantly. As a result, human workers can carry out their duties alongside robots, confident in the system’s safety protocols.

Cost Savings and Reduced Downtime

Unexpected outages and repairs can be expensive. The SX-910’s predictive analytics help foresee potential issues before they become critical. By evaluating wear-and-tear indicators captured in real-time, you can schedule maintenance during convenient intervals. This proactive approach minimizes unplanned downtime and curtails maintenance expenses in the long run.

Integration Strategies for the Robot-Eye SX-910

Retrofitting Existing Systems

Some facilities operate older, time-tested robots that lack modern vision capabilities. Instead of replacing functional equipment, the Robot-Eye SX-910 can be retrofitted. Its universal compatibility and standard communication interfaces simplify integration. This approach offers an affordable way to bring your older robotic units up to speed with cutting-edge vision technology.

Building a Connected Factory

Modern manufacturing is no longer confined to manual processes. By deploying a network of Robot-Eye SX-910 sensors across the production floor, you can collect valuable data on machine performance and product quality. This data can be funneled into manufacturing execution systems (MES) or enterprise resource planning (ERP) software, enabling real-time decision-making. The result is a more agile, connected factory, ready to adapt to shifting market demands.

The Future of Robot-Eye SX-910 in Robotics

As industries embrace advanced automation at a larger scale, the demand for reliable vision systems will continue to rise. The Robot-Eye SX-910 is poised to evolve in tandem with emerging technologies like artificial intelligence (AI) and big data analytics.

Ongoing Research and Development

Manufacturers of the SX-910 are already exploring ways to enhance its speed, resolution, and algorithmic capabilities. Future versions may integrate deep learning models that automatically refine object recognition, leading to better detection rates and faster processing times.

Collaboration and Partnerships

Robotics companies increasingly partner with sensor providers to build holistic solutions. The Robot-Eye SX-910’s universal compatibility makes it an attractive choice for such collaborations. Through partnerships with software developers and AI firms, we can expect more specialized applications in areas like autonomous mobile robots, drone navigation, and even surgical robotics.

Conclusion: Embrace the Vision Revolution

The Robot-Eye SX-910 is more than just another component in the automation chain—it’s a catalyst for reimagining how robots see and interact with the world. With its high-resolution imaging, advanced data processing, and rugged durability, the SX-910 stands at the forefront of modern robotics. By providing unprecedented levels of precision and reliability, it helps manufacturers overcome production bottlenecks, reduce costs, and maintain rigorous quality standards.

As we edge closer to a future shaped by AI and connected systems, integrating powerful vision sensors like the Robot-Eye SX-910 will be essential for businesses seeking a competitive edge. Its potential for boosting efficiency, enhancing safety, and unlocking new capabilities ensures a lasting impact on industries from electronics and automotive to healthcare and logistics. In short, if you’re looking to revolutionize your manufacturing line or robotics project, investing in the Robot-Eye SX-910 is a step toward a more efficient and technologically advanced future.

For more insights and updates on emerging trends in robotic vision and industrial automation, you can visit the International Federation of Robotics (IFR).