Robotic arm technology has come a long way since the first industrial robots began working on automotive assembly lines. What was once an emerging concept is now a versatile solution used across various industries—from manufacturing and healthcare to aerospace and even consumer applications. In today’s fast-paced, technology-driven world, robotic arms have become indispensable for operations that demand efficiency, precision, and safety. This article delves into the concept of arm robots, their evolution, potential applications, and the future trends shaping this fascinating field.

Table of Contents

Introduction

Robotic arms, also known as mechanical arms, are programmable devices designed to perform tasks that are often repetitive, dangerous, or require high precision. Although initially developed for industrial use—particularly in automotive manufacturing—arm robots have diversified significantly. They can perform intricate medical procedures, harvest crops, assemble delicate electronics, and even fix satellites in space.

Historical Background

The first industrial robot, called the Unimate, was introduced in the 1960s to automate die-casting operations in the automotive sector. This revolutionary invention paved the way for robotics research and propelled innovations in actuator design, control systems, and human-machine interfaces. Over the decades, advancements in computing power, sensor technology, and artificial intelligence have contributed to the development of highly sophisticated robotic arms that can adapt to various tasks with remarkable flexibility.

Key Components

Robotic arms may vary in shape, size, and functionality, but they generally share several critical components that enable them to operate efficiently. Understanding these components is essential for anyone interested in implementing or upgrading robotic arm systems.

Actuators and Motors

At the heart of every robotic arm are actuators—mechanical devices that convert energy (electric, hydraulic, or pneumatic) into motion. Electric motors are the most common actuators in modern robotics due to their precision, reliability, and ease of control. High-torque motors, often equipped with servo mechanisms, help achieve the necessary movement accuracy.

Key Points

- Servo Motors: Offer closed-loop control for precise movements.

- Stepper Motors: Provide simpler control but may lack the same level of precision without additional feedback mechanisms.

- Hydraulic and Pneumatic Systems: Used in heavy-duty applications where substantial force is required.

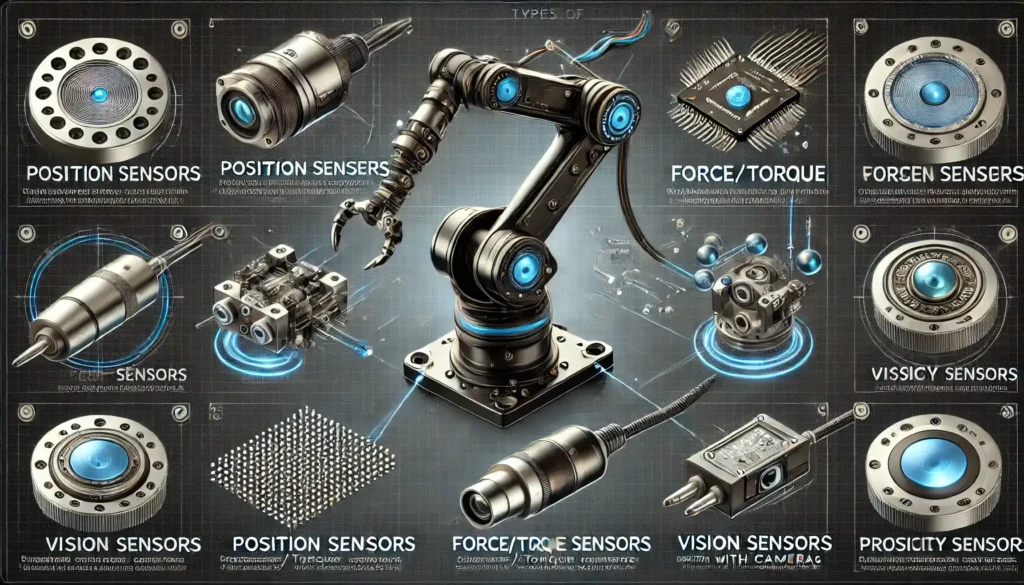

Sensors for Precision

Sensors play a crucial role in giving robotic arms the “sense of touch,” position, and sometimes even vision. They collect real-time data that helps correct the arm’s movements to maintain precision and safety.

Types of Sensors

- Position Sensors: Detect the arm’s angle and joint rotation.

- Force/Torque Sensors: Measure the force applied for tasks like gripping or drilling.

- Vision Sensors (Cameras): Offer the arm the ability to see and identify objects, improving accuracy in handling.

- Proximity Sensors: Prevent collisions by alerting the system about nearby obstacles.

Industries Benefiting from Robotic Arms

Few technologies have as broad an impact across diverse sectors as robotic arms. Below are some of the key industries that heavily rely on or are increasingly incorporating this technology.

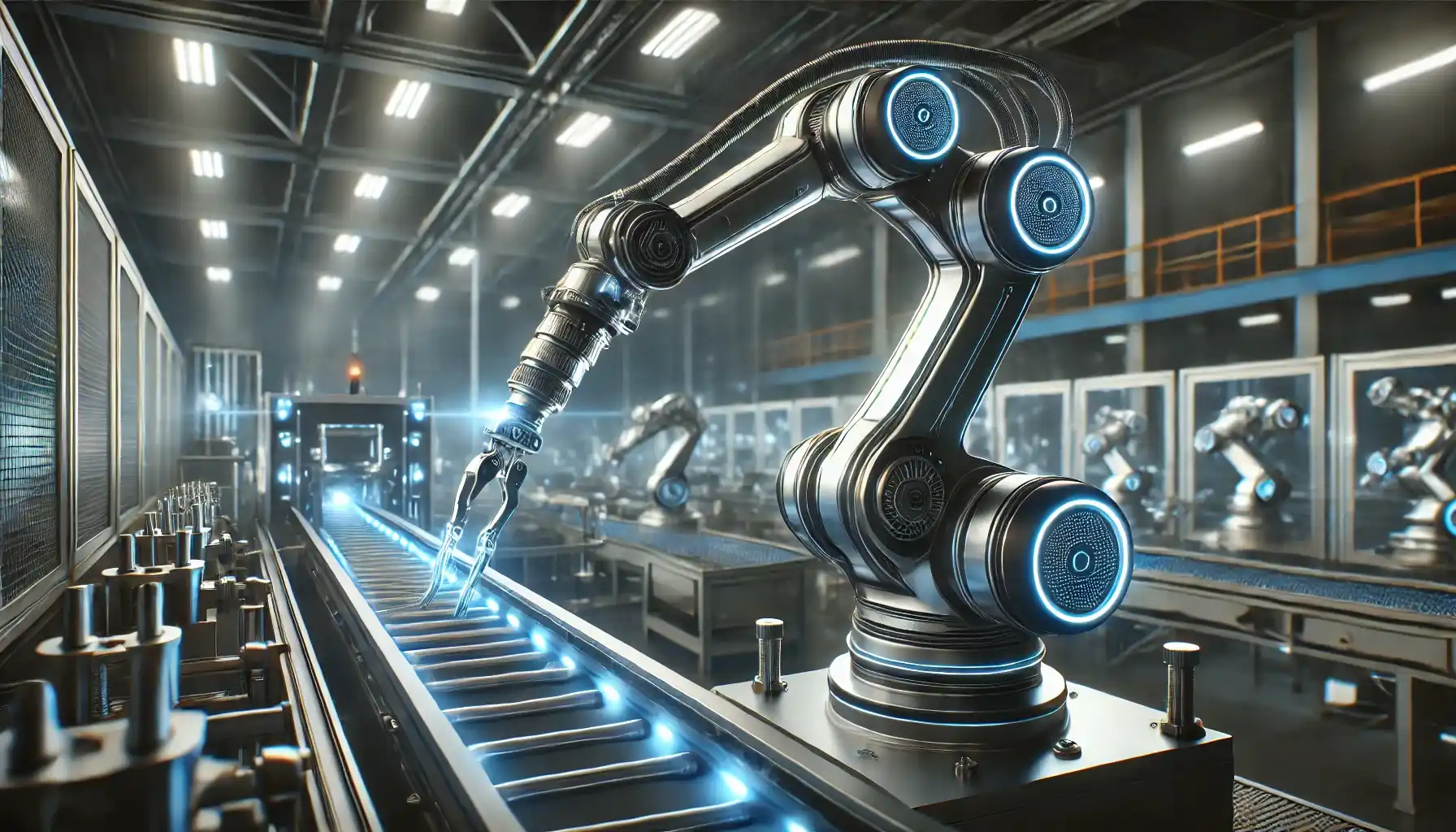

Manufacturing and Assembly Lines

The manufacturing sector remains the largest market for robotic arms. From automotive to electronics and consumer goods, robotic arms perform repetitive tasks with consistency and speed unmatched by human labor. They help:

- Automate Assembly: Efficiently assemble products such as cars, smartphones, and household appliances.

- Perform Quality Checks: With integrated sensors and AI, robotic arms can detect minor defects that might be missed by human inspection.

- Improve Safety: Reduce workplace injuries by handling hazardous tasks (e.g., welding, painting, and heavy lifting).

Healthcare and Surgery

Medical applications of robotic arms are expanding rapidly. Surgical robots provide extreme precision, reducing the risk of complications and enabling faster recovery times. Robotic arms are also used in rehabilitation to help patients with limb mobility and in prosthetics to enhance the lives of amputees.

- Robotic-Assisted Surgeries: Minimally invasive procedures, such as robotic laparoscopy, offer greater accuracy.

- Rehabilitation Robotics: Assist in patient recovery by offering controlled exercises for damaged limbs.

- Medical Research: Help in laboratory automation for testing and drug production.

Agricultural Applications

As global food demand increases, the agricultural sector has begun to adopt robotic arms to improve efficiency. From planting and harvesting to sorting and packaging, robotic arms reduce manual labor and increase yield.

- Precision Farming: Targeted use of seeds and fertilizers while minimizing waste.

- Harvesting: Identify ripe produce and gently pluck them without causing damage.

- Food Processing: Automate sorting and packaging, improving hygiene and consistency.

Space Exploration

Robotic arms are essential tools in space missions. The Canadarm on the Space Shuttle and the robotic arms on the International Space Station illustrate how invaluable these devices are for satellite deployment, repairs, and collecting samples from extraterrestrial bodies.

- Satellite Maintenance: Extend mission life by enabling on-orbit repairs.

- Asteroid and Planetary Exploration: Collect samples for scientific study.

- Docking and Cargo Handling: Transfer cargo and equipment between spacecraft.

Challenges and Considerations in Robotic Arm Deployment

While robotic arms bring numerous benefits, they also come with challenges and considerations that potential users should address early in the planning process.

Complexity and Costs

Deploying a sophisticated robotic arm system is not cheap. Costs include not only the robot itself but also installation, programming, safety measures, and ongoing maintenance. The return on investment (ROI) must be carefully calculated, considering factors such as production volume, labor costs, and time saved.

Workforce Integration and Training

Introducing a robotic arm can change the workforce dynamic. Some tasks may become obsolete, while new roles—like robotics maintenance and programming—emerge. Companies must invest in upskilling and reskilling programs to ensure that employees can effectively collaborate with their new robotic colleagues.

- Skill Development: Train staff to manage and troubleshoot robotic systems.

- Collaboration: Foster synergy between human workers and robots for maximum productivity and safety.

- Change Management: Address employee concerns through transparent communication.

Ethical and Safety Concerns

Robotic arms deal with high precision and sometimes heavy loads, so safety measures are critical. Proper guarding, emergency shut-off mechanisms, and rigorous testing protocols are essential. Additionally, as robots become more capable, discussions around job displacement and ethical considerations for AI-driven autonomy will continue to gain importance.

Future Trends in Robotic Arm Technology

The future of robotic arms is bright, driven by ongoing innovations that push the boundaries of what these machines can achieve. Here are some developments shaping the field:

Artificial Intelligence and Machine Learning

AI and machine learning algorithms enable robotic arms to learn from data and adapt to changing conditions. Instead of following a rigid set of instructions, these arms can identify patterns, predict outcomes, and self-correct errors in real time.

- Computer Vision: Sophisticated image processing for object recognition and tracking.

- Predictive Maintenance: Use sensor data to predict mechanical failures before they happen.

- Adaptive Control: Adjust operation parameters based on real-time feedback and environment changes.

Advanced Materials and Lightweight Designs

As new, stronger, and lighter materials become available, robotic arms can become more agile and energy-efficient. Advanced carbon composites, aluminum alloys, and even 3D-printed components can significantly reduce the robot’s weight without compromising strength.

- Energy Efficiency: Lighter structures require less power, reducing operational costs.

- Portable Solutions: Compact and mobile arms for fieldwork and small-scale operations.

- Durability: Enhanced resistance to wear and tear in harsh environments.

Collaborative Robots (Cobots)

The rise of collaborative robots—or cobots—represents a new paradigm in industrial and commercial settings. These robotic arms are designed to work alongside human operators without extensive safety barriers. Equipped with advanced sensors and AI, cobots can immediately halt operation if they detect an unexpected human presence or obstruction.

- Flexible Deployment: Easy to integrate into existing workflows without major infrastructure changes.

- Shared Workspaces: Humans and robots can safely work side-by-side.

- Cost-Effective: Smaller, simpler designs are often more affordable and easier to maintain.

Conclusion

From their industrial origins to modern-day applications across healthcare, agriculture, and even space exploration, robotic arms have proven to be transformative. Their ability to streamline processes, ensure precision, and reduce human risk factors makes them indispensable in today’s technology landscape. However, as robotic arms become more widespread, businesses and governments must carefully consider issues of cost, integration, workforce impact, and ethical responsibilities.

The future is undoubtedly promising: machine learning, better materials, and collaborative robots will continue to unlock new possibilities, reshaping how we live and work. As the technology advances, robotic arms will likely become even more versatile, user-friendly, and ubiquitous, serving as essential partners in innovation and progress.

Trusty Link

For more information about the latest advancements and applications of robotic arm technology, visit:

Trusted Robotics Resource